Efficient pallet packaging into a trailer requires not only knowing pallet size and truck dimensions. It’s also important to consider weight limits and choose suitable loading strategiesю

Whether you plan to stack pallets or lay them, it will affect the efficiency of your operations. Thorough planning reduces risks and improves efficiency and profitability.

Pallet Sizes and Dimensions

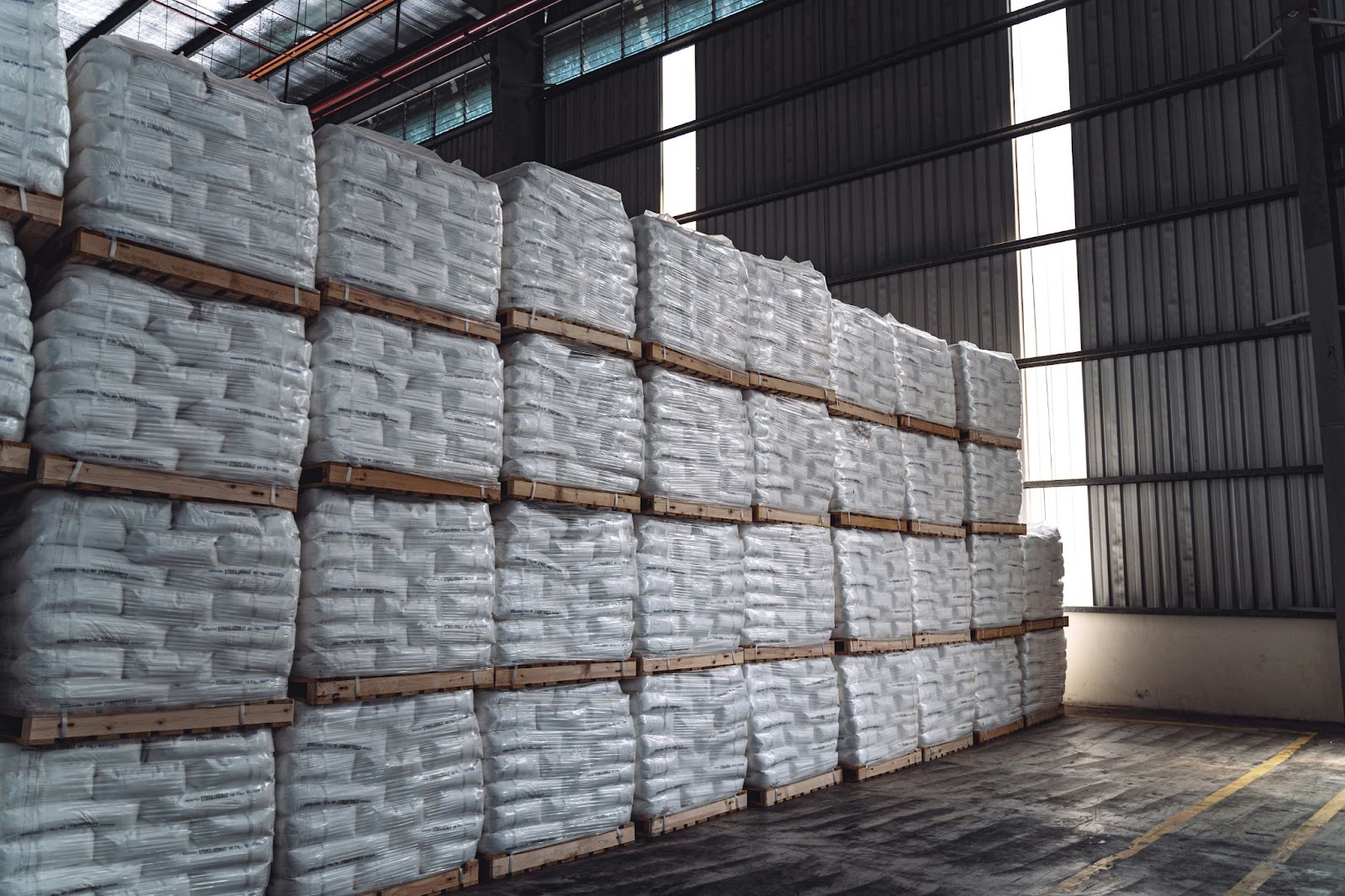

Pallets are an essential part of most cargo shipments. It’s flat structures that support goods during transportation, providing a stable platform for the cargo and simplifying the handling and transportation. In particular, pallets allow quicker loading and unloading and protect cargo during transit.

Usually, pallets are made from wood, plastic, or metal. Wooden is the most commonly used option because of its cost-effectiveness and versatility.

Pallets’ size and dimensions affect the packaging process, transportation, and storage. It also impacts the number of pallets per truck.

Common Size and Dimensions

The American pallet sizes are 48’’x40’’, 42’’x41’’, and 48’’x48’’. They typically can carry up to 4,600 lbs and weigh around 37 lbs each.

The standard pallet of 48×40 inches is in the US and Canada. It’s commonly used in various industries. 42×42-inch pallets are used in the food and beverage sectors. Their square form is suitable for drums or barrels. pallets of 48×48 inches are popular in the chemical and automotive industries, providing a base for bulkier items.

When preparing for the road, it’s crucial to understand the exact dimensions of the pallets you use. This covers their length, width, and height. In addition, the pallet size determines how many pallets fit in a truck.

Truck and Trailer Dimensions

You should also know the precise dimensions of your truck to load pallets efficiently. The size and design of a trailer also impact how it should be packed. Knowing these factors, you can optimize the space and ensure even weight distribution in compliance with safety regulations.

Moreover, the layout of the pallets also influences capacity. You can load pallets in a single row or stack them. Still, you should consider weight limits and load stability to prevent shifts.

Proper weight distribution is essential for compliance with safety standards. Overloading can lead to higher risks of cargo damage and potential fins.

In addition, custom-sized pallets or non-standard packaging might affect the overall number of pallets in a trailer.

Standard Dimensions

Usually, in freight transportation, the 53-foot trailer is used. This measures 8.5 feet in width and 9 feet in height. It’s commonly used because of its capacity to accommodate many pallets. In particular, this trailer fits 26-30 standard pallets (48×40 inches). However, the exact number varies depending on the methods and tightness of the package.

The smaller trailer, 48 feet in length, can fit around 24-26 pallets, depending on how you pack. Even small variations in size or packaging can impact the number of loaded pallets. Thus, accurate measurements are critical.

Weight Limits

In the US, trucking industry regulations set a truck gross vehicle weight (GVW) limit at 80,000 pounds. This limit includes the combined weight of the truck, trailer, and cargo.

Thus, you should consider it not to exceed the weight limits during loading.

Overloading some trailer parts can lead to safety issues and violations of industry regulations. It can affect vehicle control, especially during sharp turns or sudden stops. The imbalance also increases accident risks during driving that may result in injuries, cargo damage, and costly maintenance. Non-compliance with industry requirements can lead to fines, penalties, and even operations suspension.

Overloading or imbalance can also cause damage to the cargo or trailer. The added strain can lead to wear and tear, resulting in repair expenses and increased downtime.

During packing pallets on a truck, you should also understand the weight of pallets. A standard 48×40-inch pallet weighs between 30 and 50 pounds. With load, its weight increases to 1,000-1,500 pounds.

Loading Techniques

Proper packing pallets on a truck is essential for efficiently using your truck’s capacity. How you pack pallets into affects the number of fitted pallets, the overall safety of delivery, and the efficiency of your operations. Proper loading way allows you to optimize your trailer space, ensure even weight distribution, and adhere to the regulations.

How to Maximize Pallet Fit

Maximizing the pallet number in a trailer requires careful planning and loading techniques. You should consider various factors for efficient use of your truck space.

- Truck measurements. Before loading, measure the dimensions of your truck. Outline a loading plan and define how pallets will be arranged.

- Choose the pallets. Identify the weight and size of pallets you plan to use. Choose those that would fit your truck’s dimensions.

- Optimize pallet loading. Arrange chosen pallets in a way to use a truck’s space efficiently. You can load them parallel or perpendicular to the truck’s length. You can also stack pallets, if the load allows. Ensure they’re stable and the weight is distributed evenly.

- Secure the load. Use securing methods like straps, shrink wrap, or cargo nets. This prevents shifting during transit and reduces the risk of cargo damage.

- Use load planning software. Leverage load planning software or tools to visualize and optimize cargo arrangement. These tools can help calculate the best way to load for your truck’s dimensions.

- Make adjustments. Load a few pallets and review the results. Test different packing pallets on a truck methods to define the best approach for your trailer.

Floor Loading and Hand Packing

Floor loading refers to the option when goods are placed on the truck floor without pallets. In some cases, it can be more effective to maximize space. This method is suitable when maximizing cubic space is essential. With it, more loads can fit in a trailer. However, this method requires careful hand packing to ensure stable and evenly distributed cargo.

Floor loading also requires careful planning, even if the pallets aren’t used. You should have plan how to arrange the goods to use a space efficiently and maintain safety.

While this option can provide space savings, ensuring safety compliance is important. Proper packaging and securing are essential to avoid damage and ensure adherence.

Conclusion

Understanding how many pallets per truck you can fit is essential for your logistics optimization. You should consider several aspects, such as proper packaging, pallet size, trailer dimensions, weight distribution, and loading techniques. The choice of pallets, the cargo layout, and the securing method are also essential in pallet loading.

You should plan to load carefully to ensure even weight distribution and prevent cargo dimensions shifts during transit. This will help to avoid legal penalties for non-compliance or legal issues with clients amid cargo damage.

LAX Freight will help to optimize your transportation, providing efficiency and safety. Whether you need to calculate how many pallets fit in a truck or ensure compliance with regulations, we’re ready to help.

Contact us now to upgrade your logistics.